Common Rail Systems

We offer you custom-made complete Common Rail systems including injectors, high pressure pumps, high pressure piping and electronic control unit from one source.

Common Rail Systems for new engines

We develop and produce Common Rail injection systems for OEMs (Original Equipment Manufacturers) of Diesel, Dual Fuel and Heavy Fuel Oil engines.

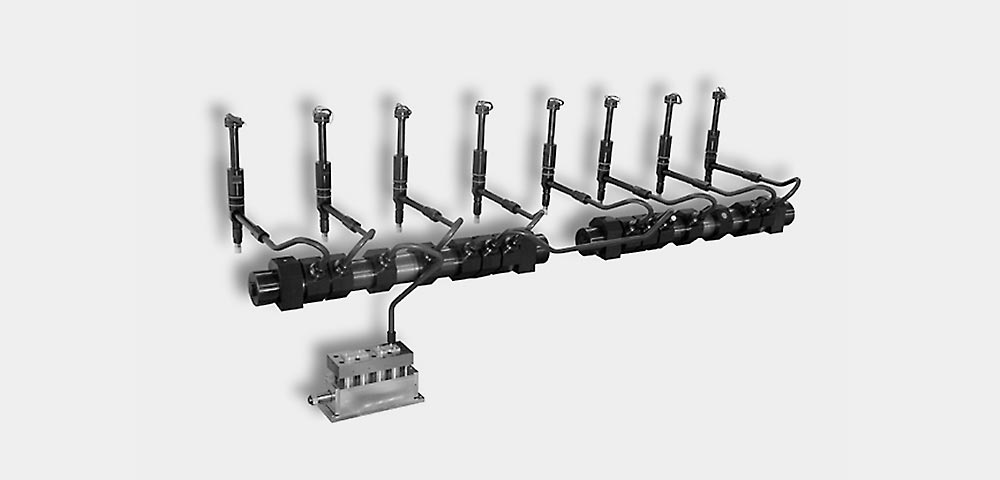

Common Rail Micro Pilot System for Dual Fuel engines

Innovative Common Rail Micro Pilot system for gas ignition in Dual Fuel engines for marine and stationary power applications. Thanks to our proprietary Wave Dynamics and Dampening System (WDD), the injection system can be built without a high pressure rail and is equipped with high pressure pipes. The high pressure pump is either driven directly by the engine or with an electric motor. All high pressure piping is laid out double walled for enhanced safety.

| Number of cylinders | L6 to V20 |

| Common Rail system pressure | 1000 to 1200 bar |

| Diesel Micro Pilot injection quantity | only 0.5 to 3% of the rated cylinder power |

Common Rail Systems for retrofit of existing engines

All our Common Rail injection systems to retrofit existing engine types come with the following features:

Uniquely designed Common Rail injectors for these engines perfectly fit into the existing cylinder head without any modifications required. The high pressure pump is driven directly by the camshaft. All high pressure piping is laid out double walled for enhanced safety. The control electronics regulate the injection system for most efficient and smooth engine operation at all load points.

Common Rail Retrofit System for GE 7FDL locomotive engines

Complete Common Rail injection system for retrofit of GE 7FDL engines, which are mainly used for locomotive propulsion. – Enhanced service life of the engine’s drive train and of the complete power pack thanks to precise and optimized electronic control of the injection parameters at every load point

| Number of cylinders | V12 or V16 |

| Engine power at the crankshaft | 3200 to 4400 HP |

| Common Rail system pressure | 1600 bar |

| Fuel savings over all load points (combined) | 6 to 7% |

| Black smoke emissions reduction over all load points | 50 to 90% |

| NOx emissions reduction at full load | 20 to 30% |

| CO emissions reduction at full load | 90% |

Common Rail Retrofit System

Complete Common Rail injection system for retrofit of ALCO engines, which are mainly used for locomotive propulsion. – Enhanced service life of the engine’s drive train and of the complete power pack thanks to precise and optimized electronic control of the injection parameters at every load point

ALCO 3100/3300/3600 HP locomotive engines

| Number of cylinders | V16 |

| Engine power at the crankshaft | 3100/3300/3600 HP |

| Common Rail system pressure | 1600 bar |

| Fuel savings over all load points (combined) | 5 to 10% |

| Black smoke emissions reduction over all load points | 50 to 90% |

| NOx emissions reduction at full load | 20 to 30% |

| CO emissions reduction at full load | 90% |

Common Rail Retrofit System for DEUTZ

Complete Common Rail injection system for retrofit of DEUTZ 616 and 628 engine series, which are widely used in marine and stationary power applications.

The benefits of the conversion to our Common Rail injection system have been published by DEUTZ in Paper No. 233 at the CIMAC Congress 2004 in Kyoto.

Enhanced service life of the engine’s drive train and of the complete power pack thanks to precise and optimized electronic control of the injection parameters at every load point.

DEUTZ 616 and 628 engine series

| Number of cylinders | L6 to V16 |

| Common Rail system pressure | 1600 bar |

| Fuel savings over all load points | 5 to 15% |

| Fuel consumption | below 190g/kWh at full load |

| Black smoke emissions reduction over all load points | 50 to 90% |

| NOx emissions reduction at full load | 20 to 30% |

| CO emissions reduction at full load | 90% |