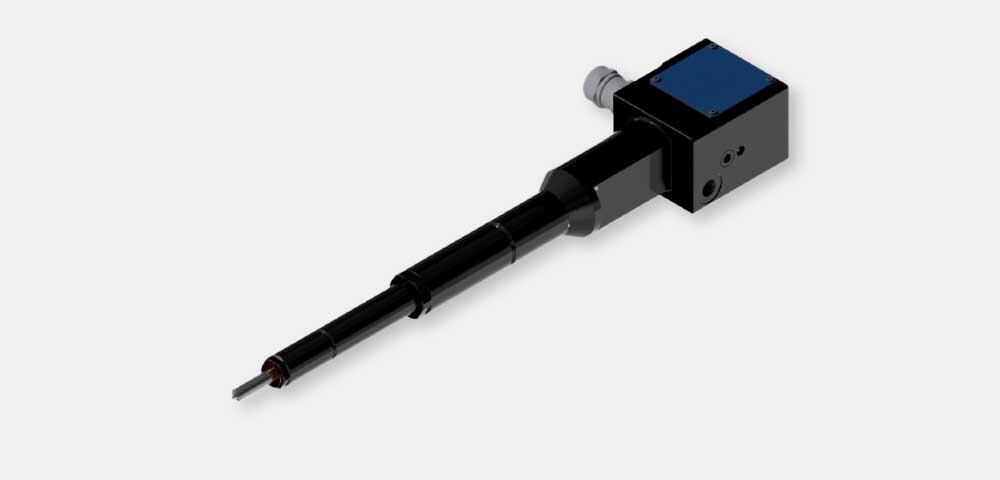

Injectors

Diesel Injectors for Micro-Pilot Systems and Main Injection Systems

Due to their highly flexible design, our injectors are suitable for any installation space. This results in minimal or no effort for the engine manufacturer to adapt the cylinder head.

Thanks to our patented valve, high injection rates can be achieved with short injection lengths. Due to the very short closing delay of the injector, the exhaust gases are much cleaner than with other injectors.

Micro Pilot Injector

| Injection quantity | 150 | mm3/shot |

| Working pressure | 1000 | bar |

| Control leakage | 30 | mm3/shot |

| High pressure inlet | Top feed | |

| Lifetime | 27000 | hours |

| Nozzle diameter | 9.2 | mm |

Injector for Railway Applications

| Injection quantity | 500 | mm3/shot |

| Working pressure | 1600 | bar |

| Control Leakage | 50 | mm3/shot |

| High Pressure Inlet | Top Feed | |

| Lifetime | 22000 | hours |

| Nozzle Diameter | 12.8 | mm |

Hydrogen injectors

First Generation

In 1992 Ganser CRS AG developed its first hydrogen injector. The control was hydraulic and inspired by the control already used for our diesel injectors.

This injector was installed in a truck engine and ran for many hours. This laid the foundation for further developments and our entry into alternative fuel injection technology.

Second generation

Since 2020 we have been developing our second generation of hydrogen injectors. Two different main concepts have been implemented, which differ primarily in the control system.

In version 1, the nozzle needle is actuated directly by the solenoid. This allows a simpler design and does not require additional oil connections.

Version 2 is hydraulically controlled. This means that the nozzle needle is partially in oil and is set in motion by means of pressure differences, similar to diesel injectors. Thus, the force applied by the solenoid is lower, resulting in a compact design.

Hydrogen injector

| Injection quantity | 550 | mg/shot |

| Working pressure | 60 | bar |

| High pressure inlet | Side feed | |

| Lifetime | tbd | hours |

| Nozzle diameter | 17.7 | mm |

Special Assignments

For special applications, we are happy to develop an injection system for the application specified by the customer. Whether gasoline, kerosene or heavy oil fuel, low or high operating parameters, we adapt our components to our customer’s engine.

Kerosene injector

| Injection quantity | 5 | mm3/shot |

| Working pressure | 500 | Bar |

| Control leakage | 3.5 | mm3/shot |

| High pressure inlet | Side feed | |

| Lifetime | tbd | hours |

| Nozzle diameter | 7.5 | mm |

| Fuel | Kerosene |